- Home

- Corporate Overview

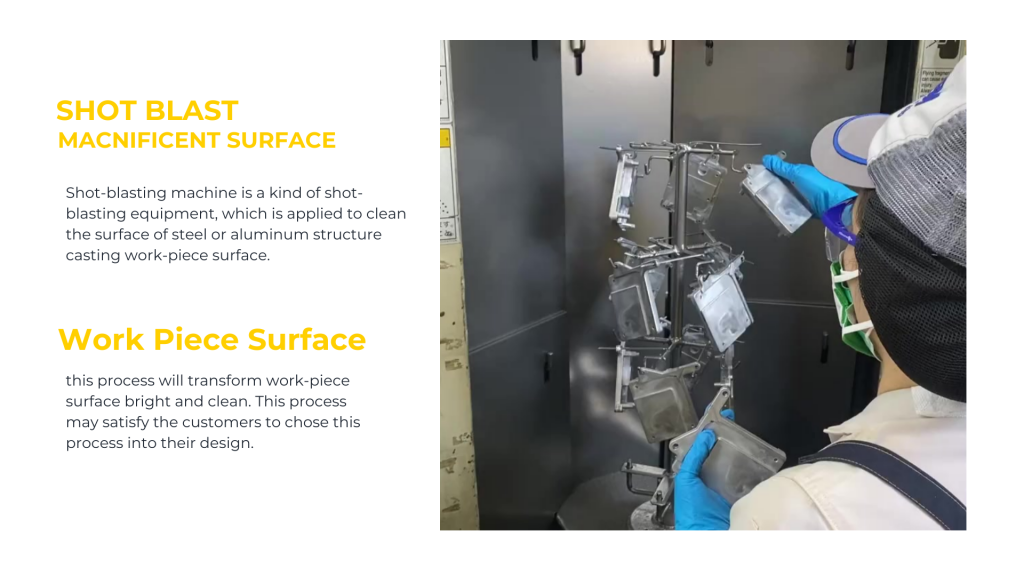

- Our Production

- CSR

- News&Activity

- Contact

- - <img src="data:image/png;base64,iVBORw0KGgoAAAANSUhEUgAAABAAAAALCAMAAABBPP0LAAAAY1BMVEX+AAD2AADuAAD/goH9dnb7bGz5YmL3Vlb+/v74+Pjx8fE/QK+ur96XmdWMjc+Cg8l3d8YAAH1VVrdLTLM1NaotLaUhIqATE5oAACgAAHNoar8AAFrg4ODzSUnyQUHfAADnAABuUDLQAAAAVElEQVR4AQXBQQ6CQAAAsY6LynL04NH/P9AYjAnYBiBEBkKSXysgoGUUInKM5XZeZDeV3tsF2U0l07L2tZtJZDk+w3XDTu41z4DAo0YinqQSvHDCH4P0DbBHDm4aAAAAAElFTkSuQmCC" alt="ไทย" width="16" height="11" style="width: 16px; height: 11px;" />

- - <img src="data:image/png;base64,iVBORw0KGgoAAAANSUhEUgAAABAAAAALCAMAAABBPP0LAAAAPFBMVEX09PTy8fHy6+vm5+b+/v77+/v29vbf39/5vLz5fHz6qqr6UFD7QUH5NDT3lZXa2tr419f3JibT09P2WloskN4YAAAAVUlEQVR4AQXBQU7FMBBAMb90hCoW3P+csCAKfIodIBIyQJAGmPQTDHgrzca94K/keT/nWOgjmdm4VvIpwy1GXOsZ9ndYYL/Wee3IRI/fr4PQCuPmAv/RTRUh24Q4UgAAAABJRU5ErkJggg==" alt="日本語" width="16" height="11" style="width: 16px; height: 11px;" />